Par-Boiling

What is Parboiling?

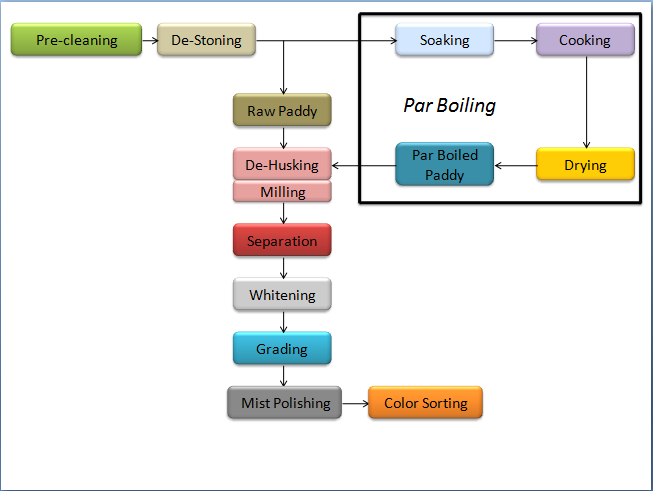

Two types of rices are available in the market. They are raw rice and boiled rice. Lot of people like the taste of foods made from boiled rice. Parboiling is the process of treating the paddy before milling including cooking the paddy using modern cookers and steam and then drying. This is optional in the rice mill. If you want to produce the raw rice alone then the installation of machinery for the parboiling is not required. But you can add this process at any time in the future.

What are the steps of Parboiling?

It contain the following sequence of three steps.

Why Parboiling?

- Huge market for boiled rice

- Breakage losses during milling of rice can be minimized

- The preservation of parboiled paddy and milled rice is longer and better than in the raw state.

- Germination is no longer possible and the endo-

- sperm has a compact texture making it resistant to attack by insect and microorganism.

- The milled rice remains firm during cooking, and its texture becomes unstiky

- Cooking time of parboiled rice is less compared to raw rice

- Its nutritional value is enhanced due to the higher content in vitamins and minerals that have spread into the endosperm during the parboiling process

- During cooking loses less starch and keeps longer

- During milling, dehusking is easier and costs less, Fewer brokens, Increased head and total rice output

- Inactivation of all enzymes which stops fungus growth and biological growth

What are the various methods of Parboiling?

A number of traditional and modern processes have been used to parboil paddy rice in different countries.The most popular and simple traditional method is.

- Soak the paddy in hot water for 6 to 8 hours on tanks of capacity 4 – 5 tons paddy.

- Drain the water and inject steam which “cooks” the paddy.

- Dry the paddy in paddy driers till the moisture level reaches 13-14%.

Shortfalls & Disadvantages in the old method are.

- Time and labour consuming.

- suitable for small plants of cap. 30 tons per day. Above that capacity they are labour intensive and of lower quality.

- Not suited for automation.

- Dependence on operators for achieving quality.

- High investment costs when we want to scale up production due to limitations in capacities of soaking tanks and driers.

- Cooking the paddy in tanks, leads to colour variation

- Hot steamed paddy is dumped in the Drier. The larger the capacity of the plant the more the dumping time. This leads to colour variation in the cooked paddy

- Small Tanks and Small Driers are required for steam rice, 4 ton Tanks and Medium Driers for boiled rice and very small steaming tanks for half boiled rice

- There will be a quality variation in each batch of paddy.

- Quality depends upon the operator’s talent.

- For high capacity plants the operator’s involvement and the workload will be high. Operator fatigue is high.

- High corrosion and erosion of driers and elevators.

- More number of tanks needed. This leads to labour intensive work.

- Shock and Extreme load on the boiler, due to open steaming.

Latest Method:

Newer methods and technologies are now being used to scale up production and achieve the required quality on a regular basis. The key concept which is used nowadays is “In- line cooking”. It is defined as the process which ensures continuous flow of paddy cooking, providing an even discharge of cooked paddy – day in and day out.- Now paddy is soaked in soaking tanks which hold 12 tons of paddy.

- The paddy is cooked in an automatic in line continuous flow paddy cooker @ 20 tons per hour.

- The cooked paddy is fed to a high efficiency fluidised bed drier for initial high moisture drying.

- The paddy is later fed to a recirculating type drier for further low moisture drying.

Attractive points in the latest method:

- The entire process of soaking, cooking and drying can be automated

- Efficiency is high and less manpower is required

- While upgrade the plant from current production to higher level no addition of work force

- Quality is high and constant